What Makes a High-Quality Printed Sticker? Key Features to Consider

In branding, packaging, and promotions, stickers have emerged as useful visual tools. Whether you are a business owner who requires labeling products or a design professional that requires striking designs, it is essential to understand what makes a high-quality printed sticker. If you have ever searched for Sticker Printing Near Me, then you know how many are out there — but not all will produce the same outcome. This is why knowing the correct features to look for will save time, money, and create remarkable outcomes. Whatever you need to find, whether durability, color quality, or professional finish, the elements leading to excellent sticker printing matter. Therefore, the next time you search for Sticker Printing Near Me in the search bar, keep these important factors in mind to choose the perfect partner of your design fantasy.

Material Quality: The Pillar of Every Great Sticker

Material choice is the most critical factor in securing quality stickers. A professional-quality sticker starts with high-grade material — vinyl, polyester, or quality paper. Vinyl is utilized because it’s more durable and withers well for indoor and outdoor environments. Paper stickers are less expensive and optimal for short-term applications.

Look for sticker printing services that offer customizable functions according to your own needs, be it waterproofing, UV protection, or tamper-evident coatings. A lower quality material can cause peeling, fading, or curling — issues which can severely affect your brand image.

Accuracy in Cutting and Printing

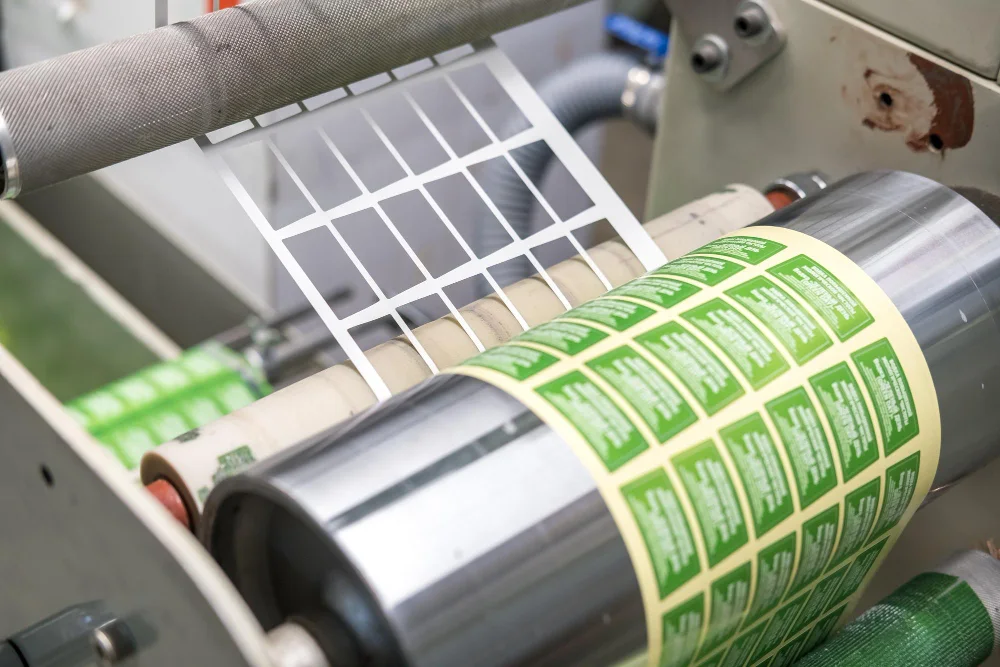

Professional finish demands non-negotiable high-resolution printing. New printing technologies such as digital or offset printing offer crisp, sharp lines and vibrant colors. In the search for Sticker Printing Near Me, ensure the provider uses advanced machines and high-precision cutting equipment to provide crispness and alignment.

Die-cutting, kiss-cutting, and special cuts offer more creativity with batch uniformity. Precise cutting also offers an absolutely fitted sticker without frayed or misplaced edges.

Adhesive Adhesion and Application Surface

Not only should a good-quality sticker look nice — it should stick well. The adhesive used should be able to suit the surface on which the sticker will be applied, be it glass, metal, cardboard, or plastic. For example, removable adhesives would be perfectly fine for temporary uses like promotional giveaways, while permanent adhesives are suitable for product labeling and branding.

Ensure the adhesive property is tested against different environmental factors such as heat, moisture, and friction. This guarantees that your stickers will not prematurely peel off or leave residue where they shouldn’t.

Finishing Options That Improve Appearance

The added finish can turn a sticker from basic to premium. Matte, gloss, and satin finishes each offer a specific texture and level of shine. Gloss finish is a mirror-like, high-gloss look that enhances bold colors, and matte finishes have a less flashy, more elegant appearance. Satin has a middle ground.

Other print shops for design also offer finishes like lamination, spot UV, or foil stamping to give the sticker durability and visual appeal. These do not only protect the sticker but also make it visually more attractive and tactile, hence increasing your branding’s possibility of being seen.

Color Accuracy and Branding Consistency

Color lies at the core of brand identity. A small change in color can impact your perception of your brand. That’s why Professional Printing and Design Services invest in color calibration tools and Pantone matching to give you precise results. When you’re printing out a big batch, make sure the colors remain consistent from the first sticker to the last.

Also, ask for proofing options or trial prints before they go for mass production. This extra step can prevent costly mistakes and ensures your design transfers perfectly from screen to sticker.

Customization and Flexibility

No two brand strategies are alike, therefore customization is a vital feature of sticker printing. A good printing firm should offer customization in size, shape, adhesion power, and finish.

Regardless of launching a new product line, adding gold trim to your packaging, or offering promotional gifts, stickers can be utilized for anything you want. An adaptable printing partner can adjust to your changing needs without loss of quality.

Environmental Considerations

With more companies placing sustainability at the top of their agendas, it is now possible to get more eco-friendly print solutions. Recycling paper, biodegradable adhesive, and toxic-free ink are some of the features that most high-end printing providers offer. Choosing sustainable options not only helps the planet but also gives your company a positive reputation among responsible consumers.

If being eco-friendly is central to your business philosophy, ask about available green options when searching for Sticker Printing Near Me.

Expert Design Support

Even the best printing machines can’t compensate for a poor design. That’s where expert designers come in. Whether you’re starting from scratch or optimizing an existing layout, access to professional design guidance can significantly improve the outcome of your stickers.

From proper bleed lines to font size and image resolution, Professional Printing and Design Services take all technical considerations into account so that your final product will be glossy and print-ready.

Final Thoughts

Quality printed sticker are an investment that is more than aesthetics — they demonstrate the professionalism, dependability, and attention to detail of your company. From choosing the proper material to choosing bright, even hues and advanced finishes, each detail matters. When you’re looking for Sticker Printing Near Me in the future, be sure to take the most critical characteristics we’ve outlined into consideration to receive the highest quality service.

For companies that need the best, Emperorprinting provides consistent solutions, great design assistance, and top-class print quality — making your sticker projects not only successful, but exceptional.

FAQ :

Vinyl, polyester, and high-grade paper are top choices. Vinyl is ideal for durability and outdoor use, while paper is great for short-term applications.

Precise die-cutting or kiss-cutting ensures clean edges, consistent shapes, and a professional look without frayed or misaligned borders.

It depends on your use—permanent adhesive for product labels, and removable adhesive for temporary uses like promos. Make sure it suits the application surface and environment.

Finishes like gloss, matte, satin, or lamination enhance visual appeal and durability. Special finishes like spot UV or foil stamping add a premium touch.

Color consistency maintains brand identity. Look for printers who use Pantone matching and offer proofing to ensure accurate, vibrant color across all prints.